The Role of Ball Bearings in Vehicles

The Role of Ball Bearings in Vehicles

Blog Article

Imagine a vehicle that operates smoothly on the road, effortlessly transitioning from acceleration to braking. What makes this seamless performance possible? One of the often-overlooked components is the humble ball bearing. These small but vital parts play a significant role in the automotive industry, ensuring that various systems function efficiently and reliably. From the wheels to the engine, understanding the Ball bearings in automotive industry is crucial for both manufacturers and consumers alike.

The Role of Ball Bearings in Vehicles

Ball bearings are mechanical devices that reduce friction between moving parts. By allowing for smooth rotation and movement, they are essential in applications ranging from wheel hubs to transmission systems. In fact, a typical vehicle may contain over 100 ball bearings, each serving a specific function to enhance overall performance.

Enhancing Performance and Efficiency

Consider the wheels of an automobile. They rely on ball bearings to facilitate smooth rotation, which is crucial for fuel efficiency. When ball bearings are employed, the energy lost to friction is minimized, allowing the vehicle to travel farther on less fuel. This efficiency is not just beneficial for the driver’s wallet; it also contributes to reduced emissions, making it an environmentally friendly choice.

[IMAGE]

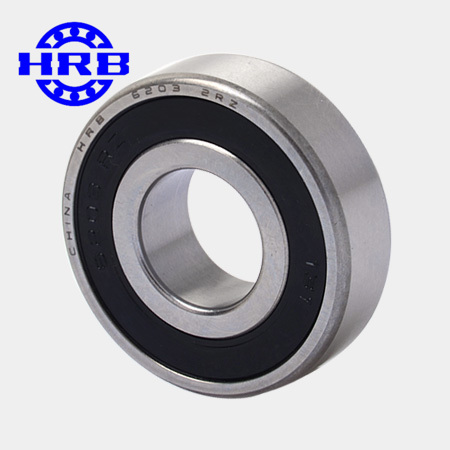

Types of Ball Bearings Used

The automotive industry utilizes several different types of ball bearings, each designed for specific applications. For example, deep groove ball bearings are commonly found in wheel hubs due to their ability to handle both radial and axial loads. On the other hand, angular contact ball bearings are often used in gearboxes and motors, where high-speed and precision are key.

Challenges and Innovations

While ball bearings are integral to automotive design, they are not without their challenges. Over time, wear and tear can lead to failure, causing significant downtime and repair costs. Manufacturers are continuously innovating to create more durable materials and designs. For instance, the introduction of ceramic ball bearings provides a longer lifespan and better performance under extreme conditions.

Quality Control in Manufacturing

The quality of ball bearings directly impacts vehicle performance and safety. As such, stringent quality control measures are essential during manufacturing. Advanced techniques, such as computer-aided design (CAD) and precision machining, ensure that each bearing meets exact specifications. This attention to detail is what enables automotive engineers to design vehicles that excel in performance and reliability.

The Future of Ball Bearings in the Automotive Sector

Looking ahead, the automotive industry is on the brink of transformation. Electric vehicles (EVs) and autonomous driving technologies present new opportunities and challenges for ball bearing manufacturers. As vehicles become lighter and more efficient, the demand for specialized bearings that can support new technologies will grow. This evolution will require ongoing research and development to create innovative bearing solutions that can keep up with the pace of change.

Conclusion

Understanding the importance of ball bearings extends beyond mere mechanics; it reflects a deeper appreciation for the engineering that makes modern vehicles possible. Their role in enhancing performance, efficiency, and safety cannot be overstated. As the automotive landscape evolves, so too will the technologies and designs surrounding ball bearings, ensuring that they remain a critical component of automotive innovation.

Report this page